Exactly How an Optical Fibre Diameter Analyser Improves Quality Control in Fibre Manufacturing

The combination of an Optical Fibre Diameter Analyser right into Fibre manufacturing processes stands for a substantial advancement in high quality control approaches. By supplying real-time, accurate measurements of Fibre sizes, this technology attends to the essential requirement for uniformity in production criteria.

Relevance of Fibre Diameter Dimension

Accurate dimension of Fibre Diameter is critical in the area of optical Fibre modern technology, as it straight affects the efficiency and integrity of Fibre optic systems. The Diameter of an optical Fibre impacts its light-carrying capacity, attenuation, and overall transmission efficiency. Accuracy in gauging Fibre Diameter ensures that the optical residential or commercial properties are maintained within specified resistances, which is essential for optimum signal stability.

Variations in Fibre Diameter can lead to increased losses as a result of spreading and modal dispersion, impacting the quality of information transmission. In high-speed interaction systems, such inconsistencies can result in significant degradation of signal high quality, bring about information errors and reduced efficiency. Consistent Fibre Diameter is essential for compatibility with adapters and splicing innovations, which are integral components of Fibre optic networks.

Quality control procedures in Fibre manufacturing heavily count on precise Diameter measurements to ensure conformity with market criteria. By carrying out robust measurement strategies, producers can boost product integrity, lessen waste, and improve general system performance. Thus, the significance of Fibre Diameter dimension can not be overstated, as it functions as a keystone in the improvement of optical Fibre innovation and its applications in modern interaction networks.

How the Analyser Works

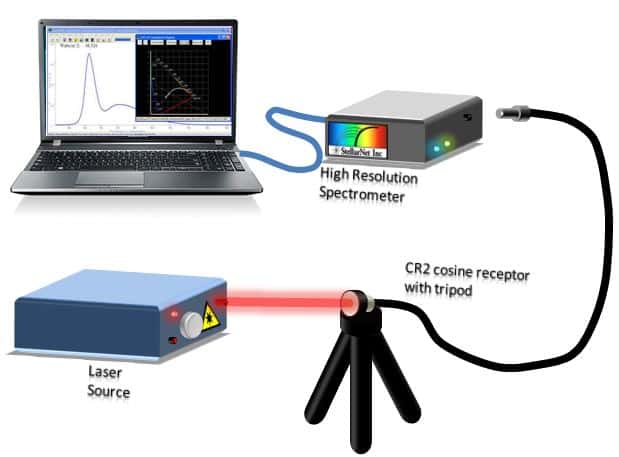

The reliable measurement of Fibre Diameter counts on advanced analytical strategies that ensure accuracy and integrity in optical Fibre production (optical fibre diameter analyser). The Optical Fibre Diameter Analyser employs a combination of laser technology and progressed photo processing algorithms to precisely analyze the Diameter of fibres as they are created

Initially, a laser light beam is routed at the moving Fibre, producing a cross-sectional darkness. The analyser records this darkness using high-resolution cams placed purposefully along the assembly line. The captured pictures are after that refined in real-time to determine the Fibre's Diameter with phenomenal precision.

The system utilizes sophisticated algorithms that represent different variables, including variations in light intensity and environmental conditions, to enhance measurement reliability. It can discover minute modifications in Diameter, such as changes that may occur throughout the production procedure.

Moreover, the analyser is qualified of managing multiple fibres simultaneously, raising throughput without jeopardizing accuracy. By providing instantaneous feedback on the Diameter, the Optical Fibre Diameter Analyser plays a vital function in preserving stringent quality control criteria, making certain that the final product meets market specs and customer needs.

Advantages of Real-Time Monitoring

While traditional approaches of keeping an eye on Fibre Diameter commonly involve lengthy post-production checks, real-time monitoring considerably enhances the performance and high quality of optical Fibre manufacturing. optical fibre diameter analyser. This proactive technique allows suppliers to determine inconsistencies in Fibre Diameter as they happen, instead of waiting till production is full to evaluate top quality

By constantly gauging the Diameter during production, producers can make certain that the fibres fulfill strict requirements, resulting in lowered variability and boosted uniformity. review Real-time tracking additionally enables prompt corrective actions to be taken, decreasing waste and avoiding malfunctioning fibers from entering the supply chain.

Moreover, this modern technology promotes boosted data collection and evaluation, providing understandings into production patterns and potential areas for improvement. Such data-driven decision-making equips suppliers to optimize processes and preserve high criteria of quality control.

On top of that, real-time tracking promotes a society of continuous enhancement within the manufacturing setting. Employees are much more engaged when they can see the effect of their job in real-time, leading to heightened responsibility and a dedication to quality. Overall, the implementation of real-time monitoring systems in optical Fibre manufacturing converts to premium item top quality and increased customer complete satisfaction.

Influence On Production Effectiveness

Carrying out optical Fibre Diameter analysers substantially improves production effectiveness by improving the manufacturing process. These devices help with continuous monitoring of Fibre Diameter, enabling makers to find variances in real-time. By determining variances without delay, manufacturing lines can be changed rapidly, reducing downtime and reducing the chance of generating faulty products.

In addition, the assimilation of these analysers into the production workflow makes it possible for much better resource appropriation. With precise Diameter dimensions, operators can optimize product usage, ensuring that sources are not squandered on flawed fibers. This precision additionally contributes to much less remodel and scrap, inevitably lowering production prices.

The automation offered by optical Fibre Diameter analysers lowers reliance on hand-operated assessments, which are frequently taxing and prone to human mistake. As a result, workers can concentrate on more critical tasks, boosting overall efficiency.

Moreover, the information created from these analysers can inform procedure renovations and help with far better decision-making. By evaluating patterns in Fibre Diameter variations, suppliers can carry out proactive steps to boost production methods and keep regular quality. In summary, optical Fibre Diameter analysers play a vital duty in boosting production performance, leading to better result and increased success.

Study and Success Stories

Throughout various industries, situation researches highlight the transformative influence of optical Fibre Diameter analysers on manufacturing processes. One prominent example is a leading telecommunications business that dealt with obstacles with irregular Fibre sizes, bring about increased rejection rates. By integrating an optical Fibre Diameter analyser, the firm attained real-time monitoring of Fibre measurements, leading to a 30% decrease in issues and significant expense financial savings.

Additionally, a research establishment focusing on sophisticated products used optical Fibre Diameter analysers to improve their speculative processes. The analyser's ability to offer thorough insights right into Fibre uniformity enabled the advancement of innovative materials with enhanced performance attributes.

These success anonymous stories highlight the essential function of optical Fibre Diameter analysers in improving quality control, enhancing manufacturing efficiency, and driving advancement across varied industries.

Final Thought

In conclusion, the Optical Fibre Diameter Analyser plays a pivotal role in enhancing quality control within Fibre manufacturing. As shown through various situation research studies, the analyser shows vital for accomplishing remarkable product quality in Fibre production.

The execution of optical Fibre Diameter analysers permitted for rigid quality control, making sure that the produced fibers met exacting market criteria.In final thought, the Optical Fibre Diameter Analyser plays a crucial role in boosting quality control within news Fibre manufacturing.